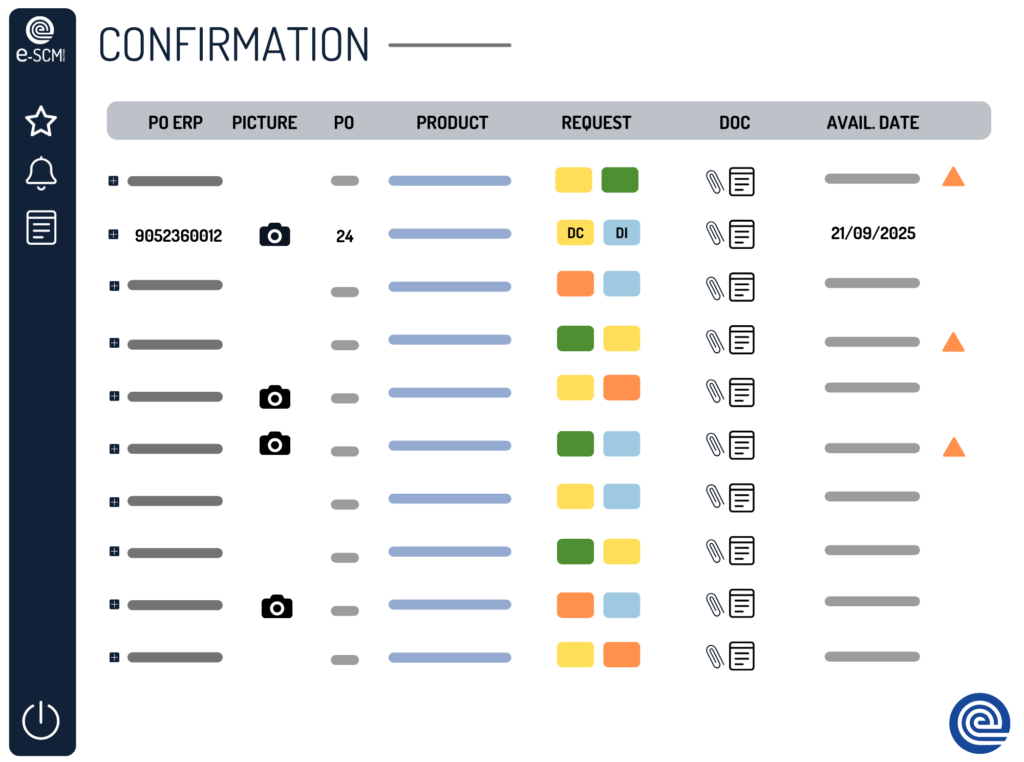

The confirmation of Purchase Orders brings together suppliers and suppliers in order to agree on the terms of current orders.

Production Monitoring allows suppliers to declare the progress of their production and suppliers to ensure compliance with key milestones in the process.

Tracking the delivery allows the logistician to have a detailed and precise vision of upcoming receptions. The latter, informed well in advance, will be able to take all necessary measures to receive the goods.

e-SCM solutions, developed in collaboration with experts, is now available in the cloud to allow its customers to benefit from the diversity and power of these solutions all over the world.

The traceability & CSR module makes it possible to map the entire process, from the manufacturing of the component or raw materials to the finished product delivered to the warehouse.

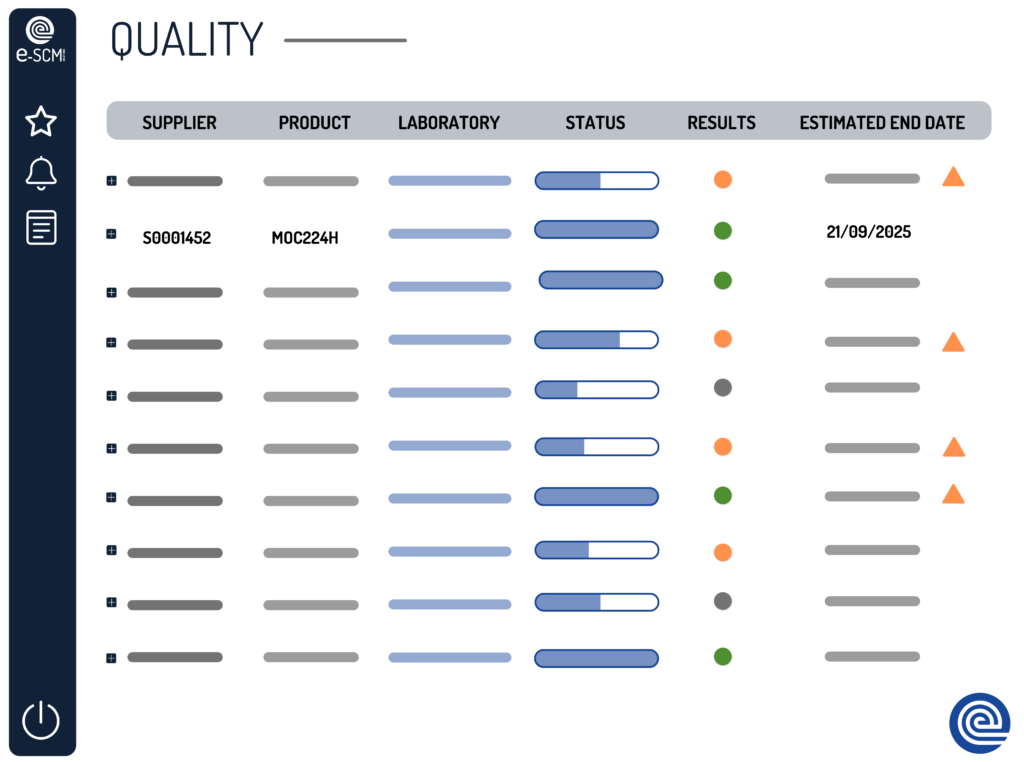

The Quality module allows detailed monitoring and management of all Quality controls carried out, of raw materials, components or finished products.

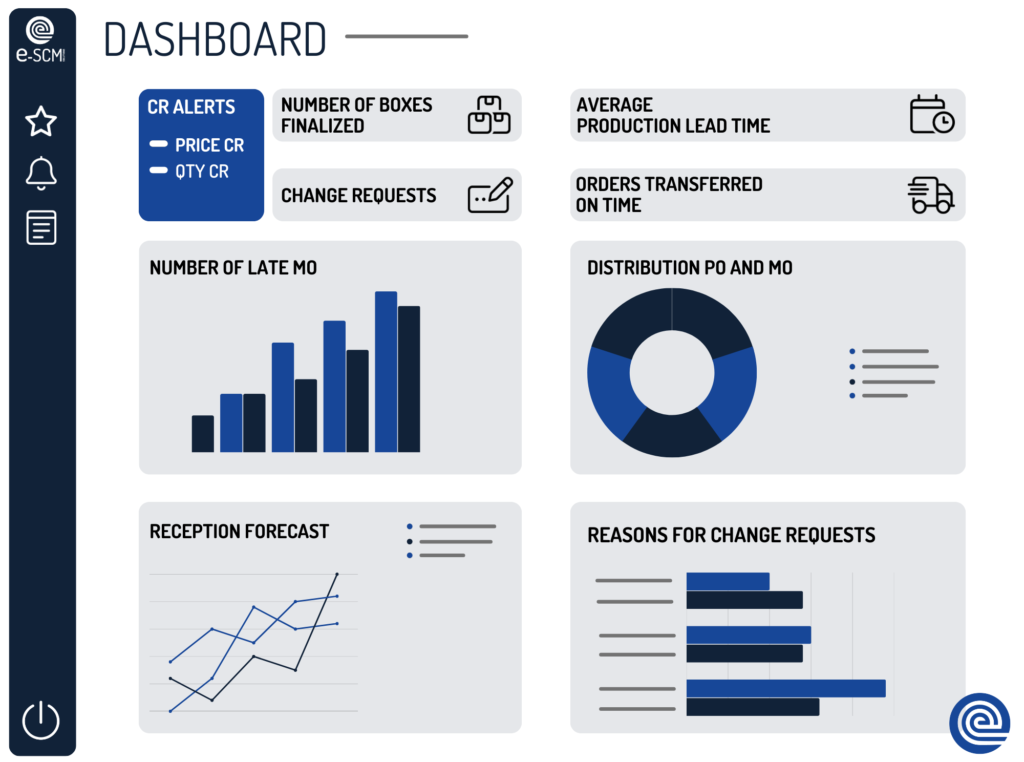

This module allows you to freely generate all types of reports related to your activity. Both to observe the past but also to analyze the present.

Digital Product Passport