The supply chain in fashion and luxury must face major challenges: a constant renewal of collections requires great responsiveness, while the fragmentation of the value chain and the multiplicity of actors complicate coordination and reduce the visibility of operations. In addition, there are strict regulatory constraints (standards, certifications, customs) and frequent shortage of shortages linked to raw materials and market fluctuations. These constraints require rigorous strategies to guarantee performance, agility and quality.

To permanently improve the supply chain, three essential levers are articulated:

These levers encourage a transverse approach involving purchases, marketing, logistics, management control and suppliers. Data sharing and reliability create a collective alignment that improves customer service rate, productivity, reliability of flows, and reduces unnecessary costs and controls.

Delegate certain controls to suppliers and use tools such as packaging plans or harmonized labeling reduces errors and double entered. In addition, better anticipation of transport optimizes the filling of containers and favors more economical modes, thus limiting costs and delays.

They make it possible to objectively assess the supply chain, to set achieveable objectives and to initiate continuous improvement while mobilizing the teams around a reliable common frame of reference.

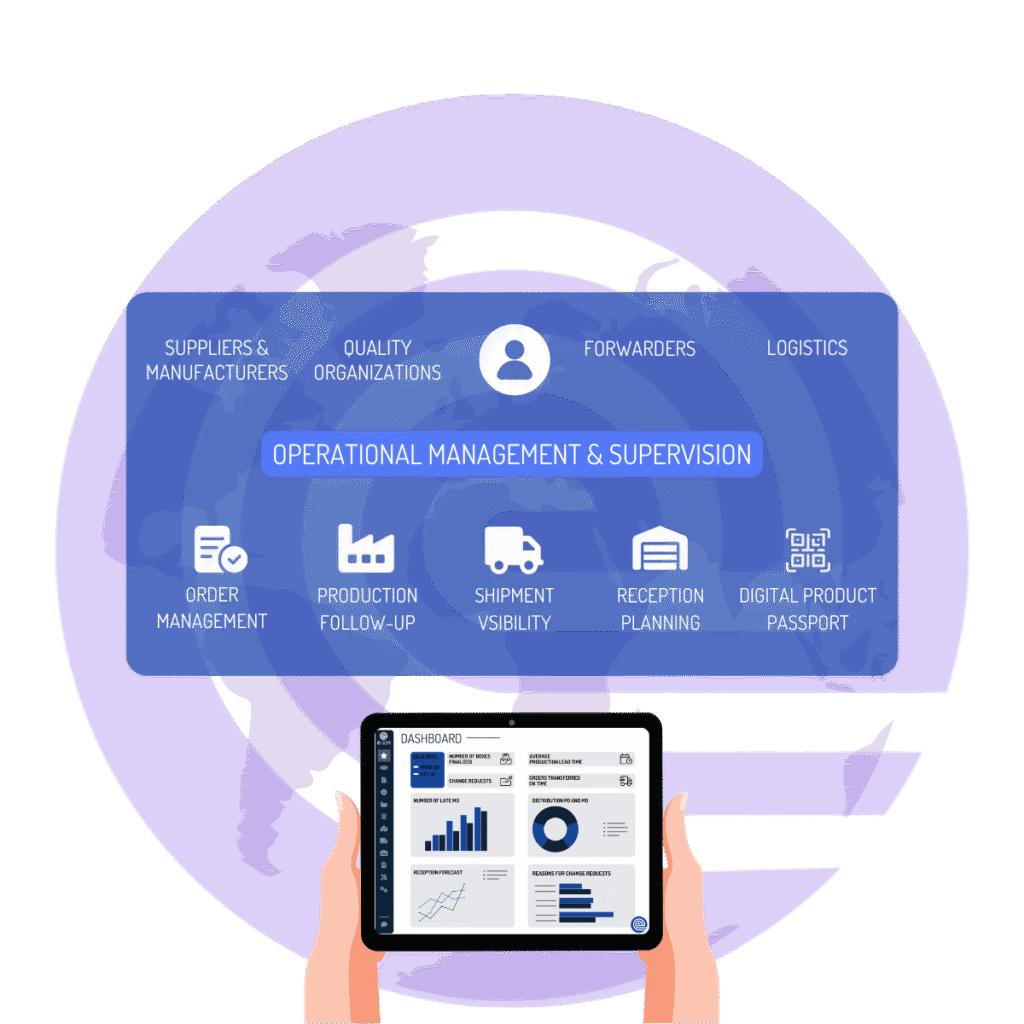

An efficient supply chain in fashion and luxury is based on rigorous planning, agile operational management and continuous analysis. With E-SCM, companies gain in robustness, agility, economic efficiency and collective alignment, thus meeting the current market requirements.