Supply chain players can consider technology as a pivot to better manage their supply chain.

The answer to this question comes in two visions: the operational and managerial .

The supply chain manager or any stakeholder in the chain is to manage operations to achieve performance and efficiency . “Supplier portal” type technologies such as the e-SCM solution make it possible to the entire supply chain in real time connected players :

○ Plan production with your suppliers

○ Monitor production and minimize risks

○ Master the quality monitoring of the chain

○ Ship and receive goods

○ Guarantee transparency and product traceability

The centralization of data from different stakeholders and the fluidity of exchanges within a platform ensure transparency throughout the supply chain. e-SCM offers configurable dashboards with monitoring of performance indicators of the brand's supply cycle. A decision-making tool that secures the process and avoids production hazards as much as possible.

e-SCM makes it possible to collect data automatically using secure APIs , and to create a and shared repository in real time. All of the company's tools can interconnect with e-SCM (PLM, WMS, freight forwarders, etc.) and increase the efficiency of the solution.

supply chain management also meets a managerial objective by providing increased responsiveness and efficiency to teams . Our solution addresses the following challenges:

○ Refocus on high value-added tasks

○ Connect the entire ecosystem

○ Promote skills development (internal and external)

○ Facilitate collaborative decision-making

Indeed, the e-SCM collaborative platform high value-added tasks , rather than on consulting and consolidating data, which can be very time-consuming. The main goal is to replace complex Excel files and simplify the data recovery process.

This immediate standardization saves considerable time, all accompanied by an efficient “ workflow ” for discussing and agreeing on modifications to an attribute of the purchase order between the different actors involved. This avoids lost emails and version problems.

This will have beneficial effects in relationships with the teams and the different suppliers who are placed at the center of the relationship . As our product manager Gilles Bidart points out , “ the fact of no longer having to run around to present information will allow us to spend a lot more time analyzing it.”

The entire ecosystem is gaining maturity and promoting the dimension of communication between each stakeholder. This all leads to a gain in productivity and an increase in skills.

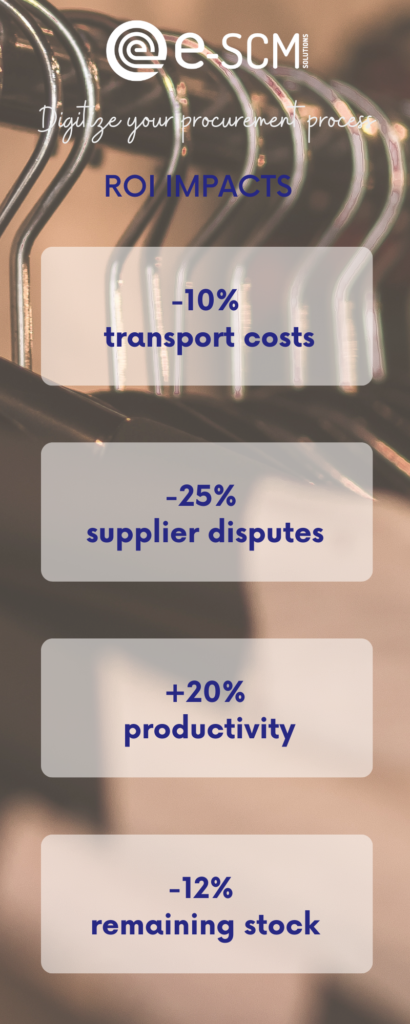

As you will have understood, the role of technology is becoming essential, facilitates collaborative decision-making and strongly impacts the returns on investment (ROI) of brands.

The positive impact on certain ROIs is a priority and the advantages developed above quickly prove it, from the first collections managed on the platform.

We rely on feedback from our clients such as Rip Curl, Petit Bateau and Aigle, to express the gains perceived by brands using the e-SCM solution.

○ Increased productivity: Improved processes for all players in the value chain and facilitated decision-making thanks in particular to integrated e-SCM dashboards offer a productivity gain of 20%.

○ More performance: A secure supply chain coping with manufacturing hazards, production monitoring limiting shortages and ensuring availability in stores ensures a 25% reduction in disputes with suppliers.

○ Reduction in the scrap rate: Thanks to the dedicated Quality process monitoring module and better control of tests and controls, we were able to see a 12% reduction in residual stock.

○ Optimized transport: Tracking the route allows visibility to the logistician on the transport capacities to be anticipated and thus makes it possible to rationalize costs by proposing shipping groupings , leading to a 10% reduction in costs. transport costs.

Overall, we are convinced that the digital transformation of all links in the supply chain is essential to face the new challenges of the textile industry and meet the demand of the end consumer .

If you want to know more about our solution, do not hesitate to make an online appointment with our business developer Antton or book a demo!