Are you a manager, operator, production director ? Then the issues that will be exposed will perhaps be familiar to you.

In a post-pandemic context, where the supply chain world has been seriously impacted, it is difficult for fashion brands to get back on track. If, in addition, you have not digitized the processes, then you are faced with issues of time, history, data security and communication with suppliers.

The use of very time-consuming methods such as Excel tables or exchanges by e-mail maximizes risks. The importance of the supply flows to be processed, or the absence of history, do not allow you to secure the data or your processes.

As a supply chain manager, it is important for you to work hand in hand with suppliers to avoid disruptions and risks. On a daily task, you could be faced with a problem, for example if your supplier no longer has raw materials and has to reduce the agreed volume for your order. You will be able to find a solution thanks to the digitalization of processes and the use of a dedicated platform.

Using a supply management solution allows you to gain efficiency and productivity. In fact, the e-SCM solution offers you a productivity (+20%) and reduces your residual stock ( –12%) . These returns on investment (ROI) have been observed in customer cases who have chosen to implement the solution in particular to promote supplier relationships but also to rationalize production .

Concretely, how does this happen ?

The e-SCM collaborative platform presents in particular the order lines which allow, for example, to see the OAs submitted to production. In the event that changes must be made, each participant is notified and can thus interact in real time on the following elements: quantity / price / delivery date / timing . All exchanges are logged in real time. There is no need to wait for an email confirmation with the supplier, as the supplier is connected to the web platform and can respond quickly.

In the example cited above, in the event of a shortage of raw materials from the supplier, with e-SCM solutions, thanks to the “SPLIT” function of the purchase order, you will be able to quickly and simply split an order while retaining the original data. You will define, with the supplier, a production and delivery schedule based on the production capacity of the factory, the replenishment times of the Raw Material and the delivery schedule expected by the distribution channels.

This function is found at all stages of the process to meet the needs for flexibility, responsiveness and traceability while adapting to industrial constraints.

Production Monitoring then suppliers to declare the progress of their production and suppliers to ensure compliance with key milestones in the process . They allow you to authorize or block certain actions, depending on their validity status. Thus, as long as the production indicators linked to a key stage are not validated, the launch of production and/or shipping is impossible.

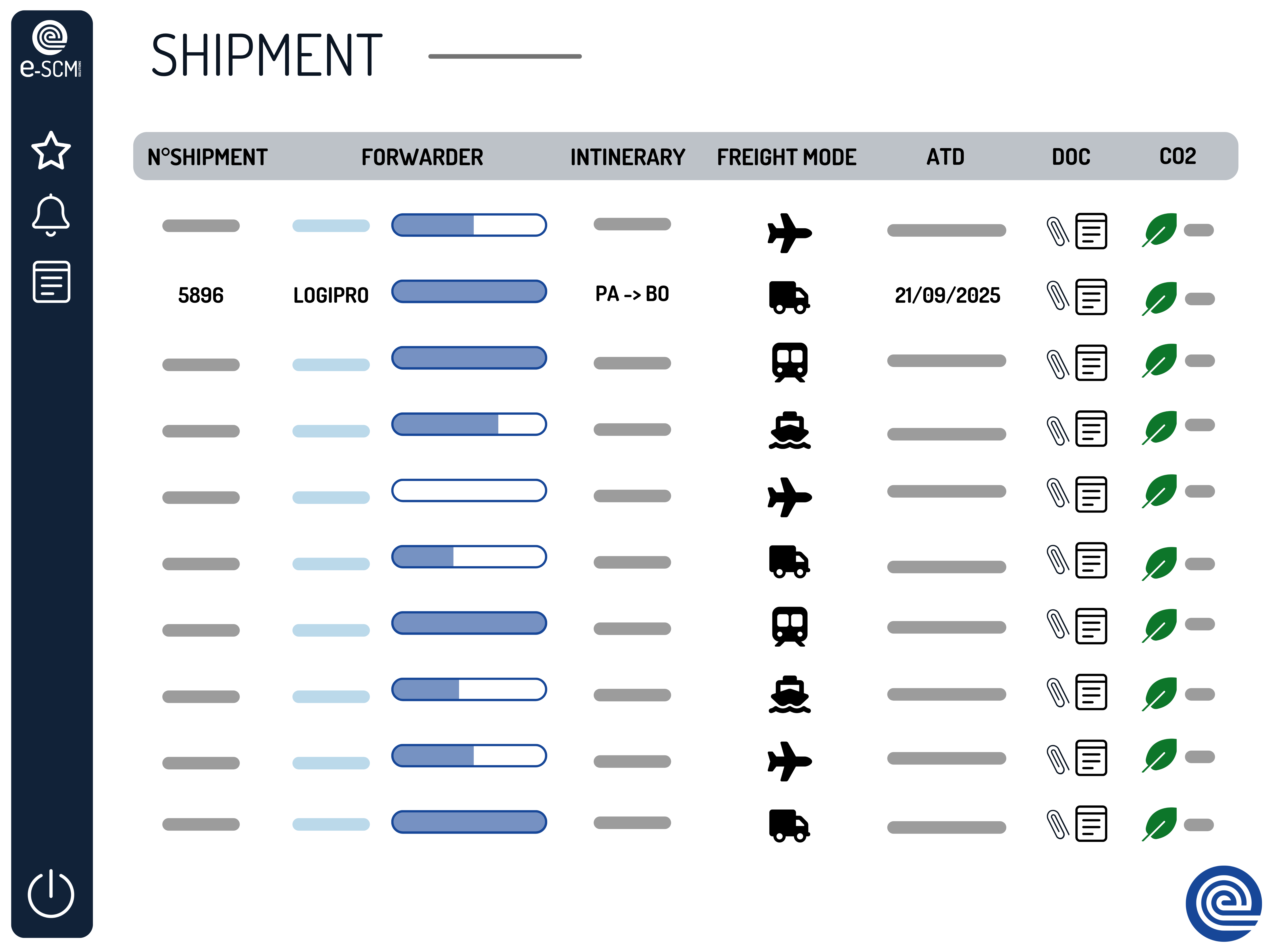

The platform will allow suppliers to give visibility to freight forwarders on the volume and quantities to be shipped so that they can anticipate and organize the necessary transport capacity . Logistics will be able to manage the transport process from the platform to the precise planning of warehouse deliveries, including appointment scheduling. This strong point of the e-SCM solution is based on its standard version which integrates a transport management system (TMS) that can easily connect with freight forwarders.

As previously stated, you will discover in your daily life the functionalities of the platform to be responsive and productive, as well as real support for the brand. You will be able :

In conclusion, all these elements will allow you to facilitate your daily work, develop commitment to the brand and thus organize the supplier's work. All for a major efficiency gain. The notion of security is significant since the e-SCM platform centralizes your data and will allow you to have a history and a 360° operational vision . Finally, from a technological point of view, the scalability of the platform makes it possible to support the evolution of the brand and manage more or less significant flows!