Have you ever wondered how businesses approach their interactions with their suppliers? Imagine a fundamental change in this approach: this is what Supplier Relationship Management (SRM) represents.

Companies in the fashion and luxury sector need to stay ahead of the curve by prioritizing their supplier relationships. This emerging trend is recognized as an essential strategy to meet increasing sustainability requirements, constantly evolving regulations and the need to digitalize its supply chain.

e-SCM has developed a guide to help you implement an SRM approach within your structure and thus optimize your supply chain.

You are familiar with “Supplier Relationship Management” (SRM), in French, Gestion de la Relation Fournisseur. This strategic approach aims to optimize relationships between a company and its suppliers. It encompasses a set of practices, processes and technologies designed to strengthen collaboration, improve performance and create mutually beneficial relationships.

What sets SRM apart is its commitment to the principles of partnership and collaboration. Unlike traditional supplier management, which often focuses on contract negotiation and cost reduction, SRM takes a long-term perspective. It recognizes that suppliers are key partners in the supply chain, and that strong relationships with them can truly contribute to the overall success of your business.

Here are the 4 key elements of SRM:

Collaboration: SRM encourages close collaboration between the company and its suppliers. Instead of simply imposing requirements, it aims to create an environment where both parties work hand in hand to achieve common goals.

Performance: At the heart of SRM, performance management is essential. This involves regularly evaluating and measuring the performance of your suppliers to ensure that they meet your standards in terms of quality, time and cost.

Strategic partnership: SRM aims to transform your suppliers into true strategic partners. This means a relationship based on trust, transparency and cooperation to create added value.

Risk management: SRM takes into account potential risks associated with your suppliers and seeks to mitigate them. This includes the management of operational, financial and reputational risks.

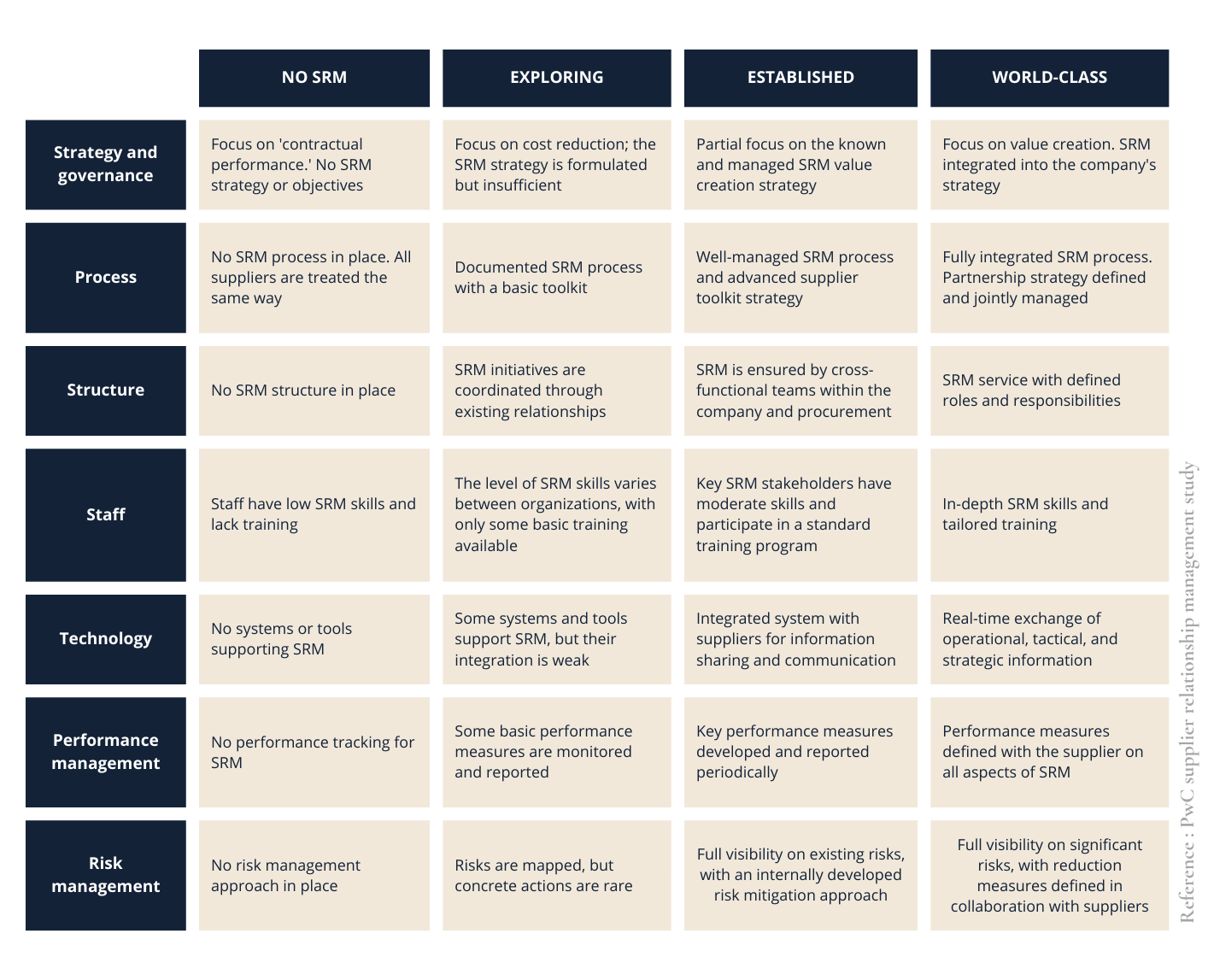

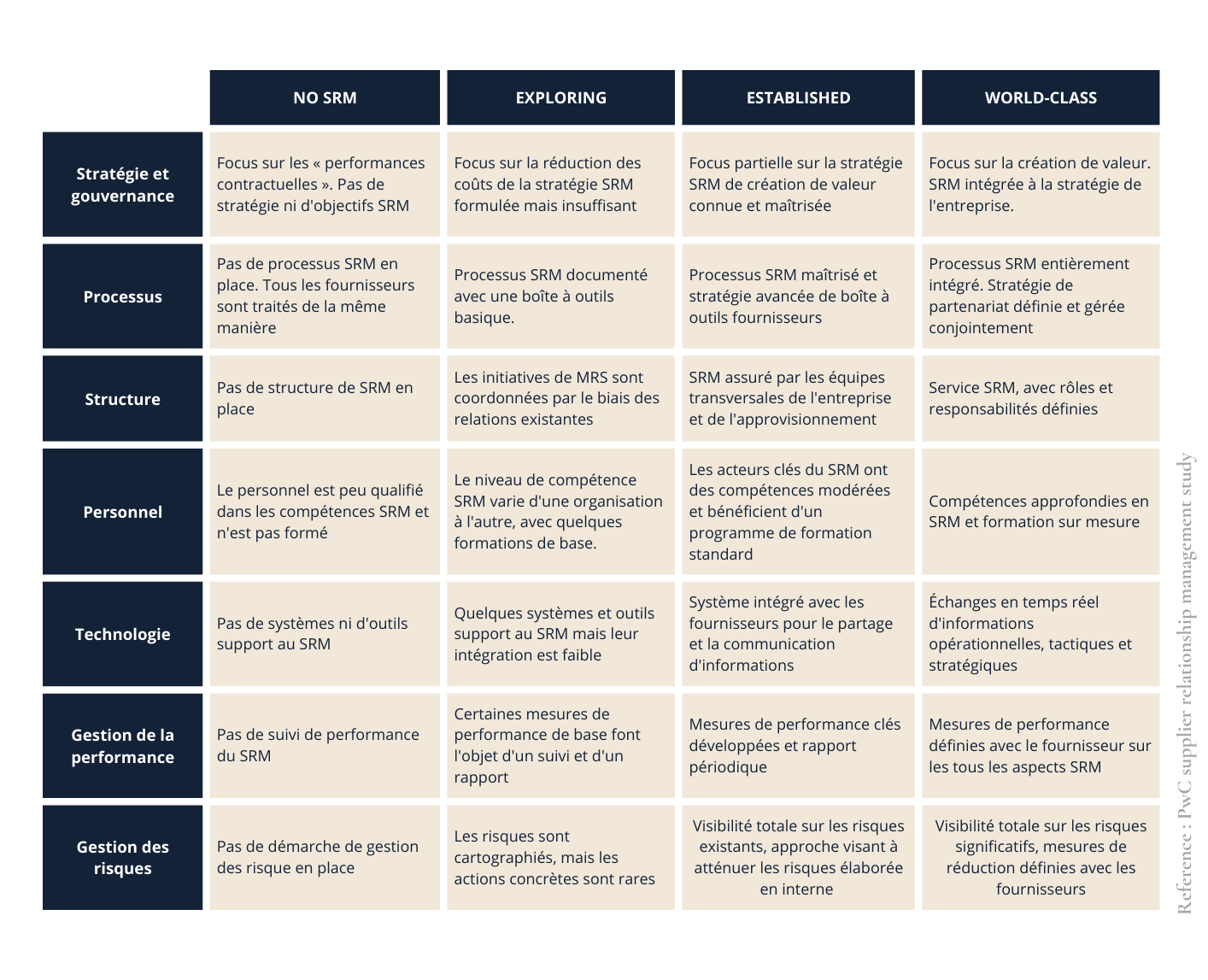

Assessing the maturity level of your supplier relationship management (SRM) is essential to identify areas for improvement and develop effective development strategies. PwC has developed a table to assess its current level of SRM maturity using the following four levels: 'No SRM', 'Exploring', 'Established' and 'World Class'. Here are the questions to ask yourself and the level indicators to measure.

No SRM :

Description : At this level, there is no formalized strategy or process for managing supplier relationships. Interactions with suppliers are generally reactive and unstructured. Purchasing decisions are primarily based on price, with little or no consideration for factors like supplier performance, risk management or long-term collaboration.

Features :

Exploring :

Description : Organizations are beginning to recognize the importance of supplier relationship management. They are experimenting with SRM initiatives and establishing core processes to manage and improve relationships with key suppliers. However, these efforts are often limited and not integrated across the entire business.

Features :

Established :

Description : At this level, organizations have well-defined SRM processes integrated into their operations. They use tools and technologies to monitor and improve supplier performance. Supplier relationships are proactively managed, with clear strategies for collaboration and risk management.

Features :

World Class :

Description : World Class organizations have leading-edge SRM practices seamlessly integrated into their overall operations and strategies. They establish strategic partnerships with suppliers, promoting innovation and the creation of mutual value. Supplier relationship management is a key business differentiator, supported by advanced technologies and a culture of collaboration.

Features :

If you want to know more and get started with the SRM approach, download our practical guide and you will discover the key implementation steps and the tools available for effective management. Download the guide.

Supplier Relationship Management (SRM) marks a major evolution in the way companies manage their relationships with suppliers. It is much more than a simple transactional approach. SRM, as a strategic approach, aims to maximize value and forge strong partnerships, all with the aim of establishing a more sustainable and efficient supply chain.

Are you ready to transform your supply chain?