Dans un contexte de mondialisation des échanges et d’instabilité croissante des chaînes logistiques, le respect des délais dans la chaîne d’approvisionnement amont est devenu un enjeu stratégique.

La gestion des approvisionnements doit composer avec des flux de plus en plus complexes, incluant de multiples intervenants, de la production à la livraison finale sachant que tout écart de taux de services peut avoir des répercussions sur la capacité de mise en marché et donc un impact financier direct.

e-SCM Solutions propose une solution digitale robuste, conçue pour garantir un suivi fin et en temps réel des dates clés du processus logistique amont. Grâce à une interface intuitive et un algorithme de calcul intelligent, la plateforme permet une gestion proactive des délais et une coordination fluide entre fournisseurs, services logistiques, transitaires et entrepôts.

En fonction de l’incoterm choisi (FOB, EXW, DDP…), de la date attendue de réception en entrepôt et du paramétrage propre à chaque univers produit, un algorithme e-SCM permet de déduire les dates prévisionnelles de tous les jalons paramétrés et donc définir les points de passage critiques à suivre.

A partir de la date attendue de réception en entrepôt, un retroplanning se calcule automatiquement en tenant compte de tous les délais intermédiaires tels que les contrôles de préproduction, la production, la préparation des expéditions, le transport, le dédouanement, la réception entrepôts, etc… Ainsi le planning prévisionnel établi fixe les échéances à suivre au quotidien par les différents acteurs tout au long du cycle de vie de l’ordre d’achat.

Mise à jour en temps réel et ajustements dynamiques

Dans le quotidien, chaque jalon est suivi et, dès qu’un aléa impacte ou risque d’impacter le planning prévisionnel, une alerte est générée. Le retard possible ou constaté donne lieu à un recalcul de la date de réception en entrepôt prévue. Les utilisateurs, informés de l’écart entre le planning attendu et le prévu, peuvent prendre les mesures correctives pour compenser l’impact.

Ce fonctionnement permet une visibilité actualisée pour tous les acteurs de la chaîne, limitant les « effets domino » liés aux retards non anticipés.

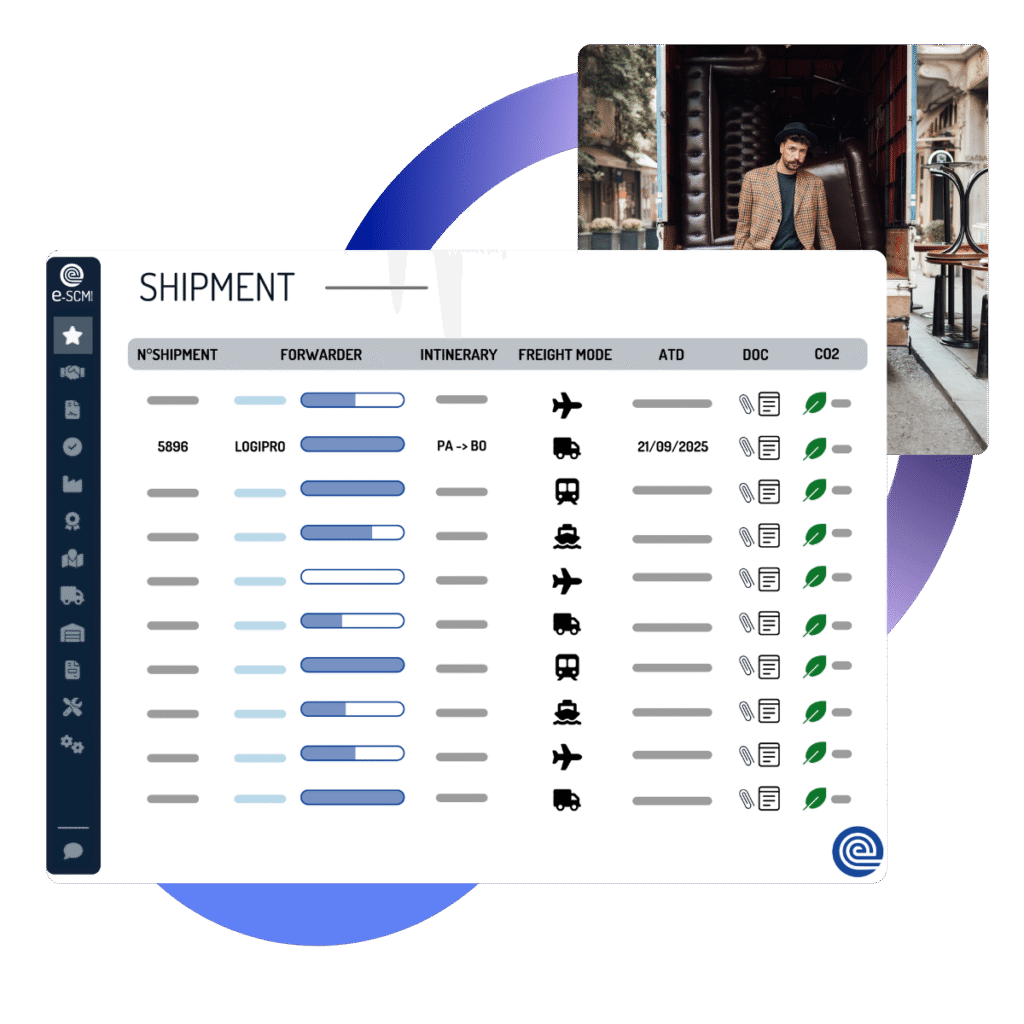

e-SCM permet donc le pilotage des étapes critiques du flux allant du passage de l’ordre d’achat au fournisseur à la réception des produits en entrepôt :

Tous ces éléments sont paramétrables dans e-SCM, ce qui permet une vision globale et actualisée du planning logistique.

L’outil repose sur un pilotage dit « par exception. » C’est-à-dire que l’utilisateur est uniquement informé de ce qui n’est pas normal ou conforme avec le planning prévisionnel. Ainsi, il se concentre uniquement sur les exceptions qui génèrent automatiquement des alertes en cas :

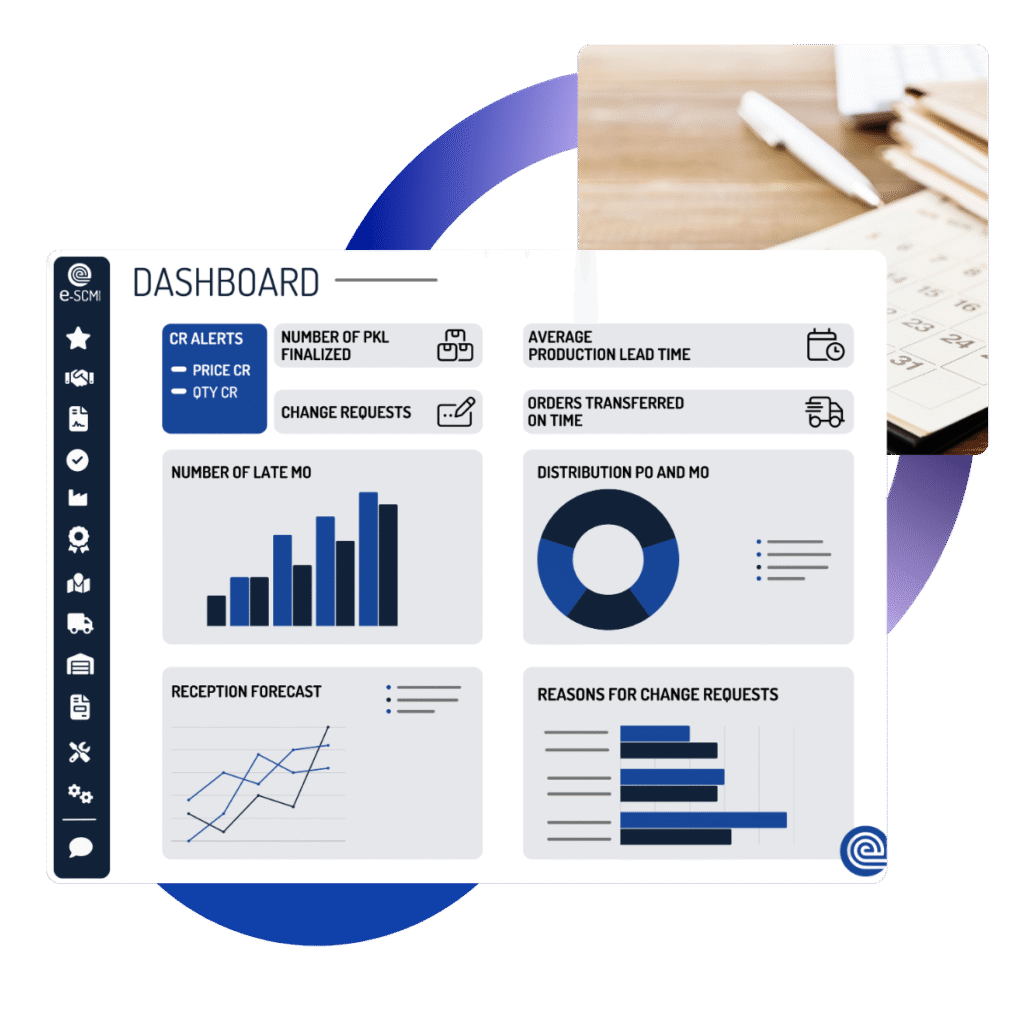

Les tableaux de bord personnalisables permettent à chaque acteur (approvisionneur, logisticien, transitaire) de suivre ses propres jalons et ainsi de se concentrer sur ses priorités. Il est en capacité de réagir au plus tôt pour prendre les décisions avec anticipation en s’appuyant sur des données fiables et traçables.

Selon une étude de McKinsey (source : McKinsey & Company, 2022), 80 % des retards logistiques dans les entreprises manufacturières sont causés par une mauvaise synchronisation des flux amonts, souvent liée à un manque de visibilité sur les dates réelles de production, de transport et de réception.

De plus, la digitalisation du suivi logistique est désormais un facteur clé de résilience : les entreprises capables de recalculer les délais en temps réel réagissent 2 fois plus vite aux aléas, réduisant significativement les ruptures d’approvisionnement.

En résumé : les bénéfices du suivi des dates avec e-SCM

Vous souhaitez fiabiliser vos délais et optimiser votre chaîne d’approvisionnement amont ?

Contactez dès maintenant nos experts pour une démonstration personnalisée d’e-SCM.