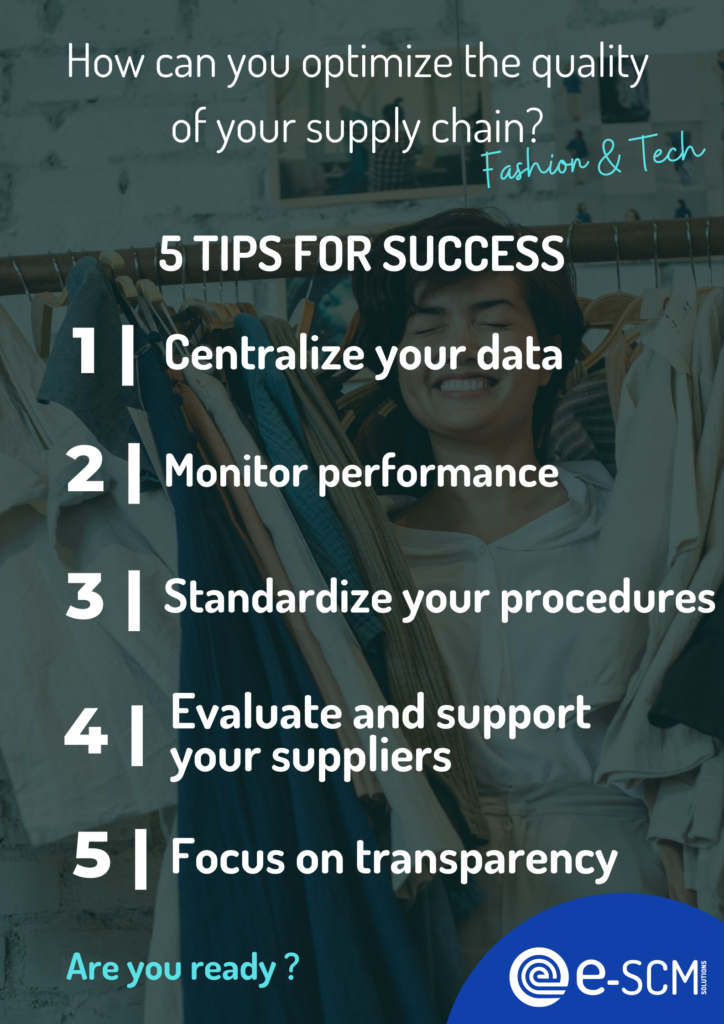

For effective quality management of its supply chain, it is necessary to set objectives throughout the process and to plan quality assurance from raw materials to the finished product:

· Ensuring consistent quality production

· Meeting regulatory requirements throughout the cycle

· Involve partners while respecting ethical standards

· Ensuring supply chain transparency for their customers

By anticipating problems and being proactive, we can prevent them from occurring.

Centralizing and consolidating quality data will allow supply teams to easily access a single source of data on quality controls throughout the process.

BENEFIT : Data speed and reliability

Centralizing data will allow for a comprehensive and cross-functional view of quality, enabling managers to make timely decisions to anticipate or stop problems that could harm production efficiency.

BENEFIT : Production cycle efficiency

Suppliers and auditors will be able to work from a standardized procedure and thus follow the various milestones necessary to meet regulatory and compliance requirements.

BENEFIT : Respect for commitments

Reports based on key indicators will allow you to track the performance of your suppliers and support them if improvements are needed.

Brands can support suppliers in their continuous improvement efforts and encourage them to evolve their practices to be more ethical and responsible

BENEFIT : Collaboration with suppliers

Consumers are increasingly turning to brands that demonstrate responsible and ethical sourcing. Being transparent about your brand's and your suppliers' adherence to quality and ethical standards will help build customer loyalty and trust.

BENEFIT : Customer trust and loyalty

The e-SCM solution helps fashion and luxury brands optimize the management of their supply chain, from order to delivery, while ensuring product compliance and time to market.

Quality control is a key success factor in procurement.

e-SCM enables real-time management and minimizes the risks of non-compliance by offering greater reliability in exchanges with suppliers through indicators and milestones to be respected during production, as well as at the time of shipment.

At any time, you get an overview of the progress of production and the results of quality controls, order by order.

The Quality module offers detailed monitoring and control of all quality controls carried out internally and by the various external laboratories for the component.

e-SCM allows you to track tests directly through the platform (creation, assignment, request, and results entry). This enables you to verify compliance with customer and regulatory requirements using the checklist you defined beforehand.

With e-SCM, you will be able to detect anomalies very early and thus implement compensatory or corrective solutions when needed.

This will allow you to monitor suppliers and support them in their improvement process.

All information is thus centralized on e-SCM, easily accessible and allowing a global view of the quality process.

As part of its new sourcing strategy, the Children Worldwide Fashion (CWF) group has initiated a project to digitize its upstream supply chain.

To achieve this, CWF opted for the e-SCM solution to strengthen the tools available to its Supply Chain teams. This solution secures data exchange, tracks suppliers, and provides greater visibility into the progress of production and the transportation of finished products. This initiative thus supports the company's ambitious development strategy.

We supported CWF in setting up the Quality mode and Jérôme Boisseau, head of the project and IT department, noted that “the expertise of the e-SCM teams, their project methodology and their mastery of the textile world were beneficial to this collaboration”.

With e-SCM, all Quality data can be used to populate a Digital Product Passport and demonstrate to the consumer the respect for Quality rules and the safety of the products.

Supply Chain management with e-SCM strengthens the traceability of operations to improve company performance and meet the obligation of transparency on CSR commitments.