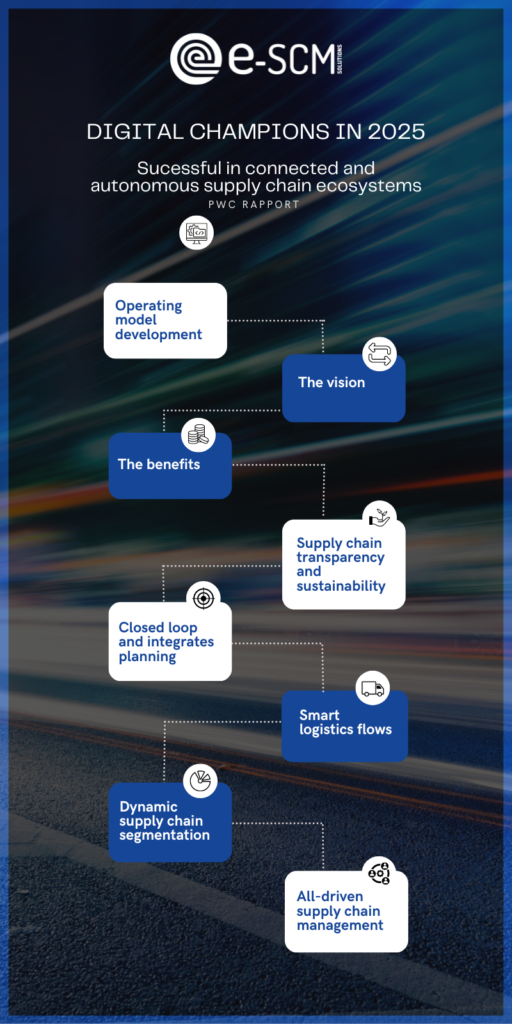

According to the report “ Connected & Autonomous Supply Chains 2025 ”, the PWC firm delivers its vision of the evolution of the supply chain by 2025, through a survey carried out among supply chain executives across the world . A focus is on the Nordic countries : only % of Nordic companies have implemented end-to-end supply chain planning, while 72% of “ digital champions ” have already done so. set up.

So where are we halfway in 2023?

Do you consider your company a “digital innovator” or “digital champion”?

Most B2B supply chains have been affected by the after-effects of the pandemic. A fourth industrial revolution is underway, with the rise of technology in all dimensions of business.

Retailers and fashion brands want to be even more customer-centric, but to meet their expectations, they must address challenges in managing their suppliers , such as contingency plans, quality compliance, logistical disruptions. Suppliers become partners rather than just interlocutors.

transformation program has become essential in a volatile environment. Linear supply chain models no longer apply to market demands and companies are seeking autonomous, connected ecosystems where all Supply Chain partners meet and contribute in real time .

All relevant internal functions will be connected using a common data network , from R&D and procurement to manufacturing, logistics, marketing and sales. Data is therefore permanently available throughout the supply chain. The study shows that most companies have taken this route and invested in new supply chain technologies digital champions ” are far ahead. They have invested in advanced supply chain technologies and will continue to do so.

Technologies are essential to make this transformation possible: they enable dynamic monitoring to sourcing raw materials, including production, delivery and even reverse flows, where companies become responsible for taking back products at the end of their life.

The benefits are visible in the short term with increased profitability and better asset utilization , and “digital champions” clearly see the benefits of supply chain optimization to drive improvements across their business . The key factors for the success of such a project are the commitment of people to the evolution of processes and change management , the choice of the solution and its scalability .

e-SCM solution , dedicated to managing supplies for fashion and clothing, provides a single platform to connect your ecosystem of partners and cover the entire process: order confirmation / production monitoring / shipment management / delivery. It can be synchronized with ERP software and automatically connected to freight forwarders through API .

Our clients such as Hummel, Rip Curl, Eden Park e-SCM solution thus making it possible to integrate all partners and follow the supply until delivery to the warehouse.