Once production is completed, transport is organized, which has become critical since the numerous logistical hazards experienced during and after the pandemic. It is often the downstream part on which the brand lacks information.

How to obtain better control and visibility over the shipping organization by involving the supplier, logistics and freight forwarder at the same time?

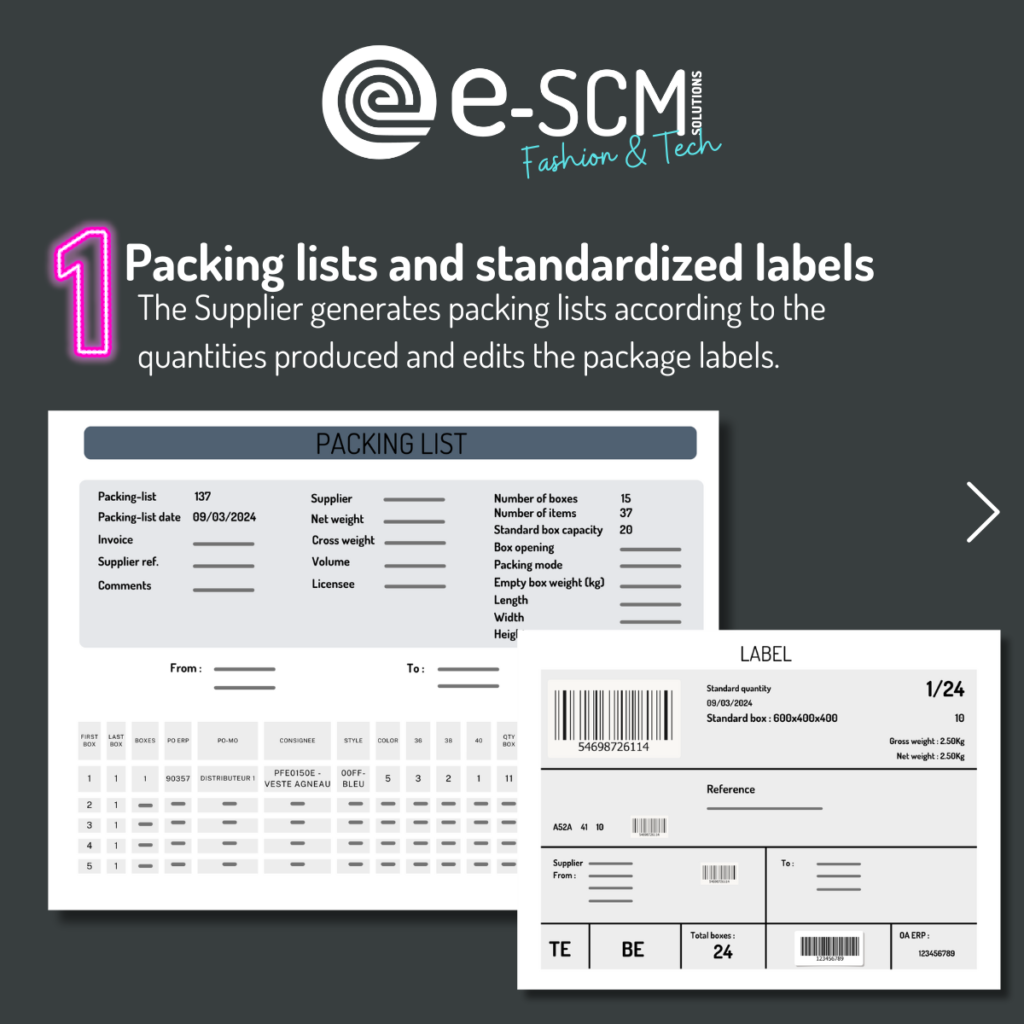

This is what we wanted to implement within the e-SCM TMS dimension into the continuity of Production monitoring. On the one hand, by facilitating the documentary management of shipments, in particular by standardizing the format of packing lists and package labels. The documentary package linked to transport and customs is also built and attached to the platform.

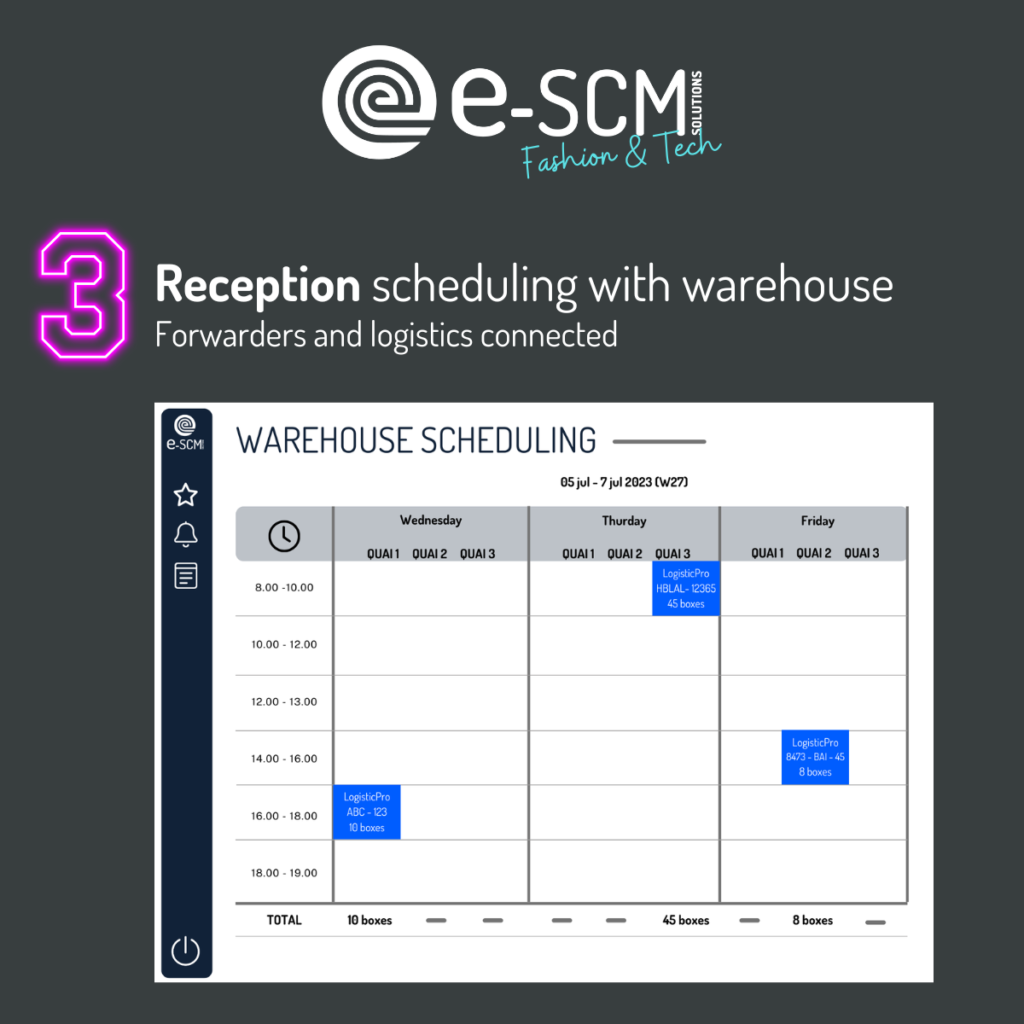

On the other hand, the supplier will be able to give visibility to freight forwarders on the volumes and quantities to be shipped so that Logistics can manage the reception schedule directly with the forwarder.

The e-SCM platform provides access to a “ Transport ” which allows the supplier , several weeks before the end of production, to book transport directly with the freight forwarder via a web services connector.

1. RESERVATION PROPOSALS

The platform first offers an automatic grouping of departures to the forwarder using the packing list and predefined criteria with a desired collection date. For example depending on the port of departure, gender, brand.

2. THE SUPPLIER SUBMITS THEIR RESERVATION

With the supplier and freight forwarder connected in real time, the supplier can submit a transport request suggesting a date for picking up the goods.

On this screen, the forwarder can filter by the name of the supplier, communicate with the supplier, attach documents. A status is also specified regarding the request:

Reservation submitted / Reservation confirmed or not / Actual transfer date entered (by the forwarder, whether there was a reservation or not)

Transport module , the freight forwarder and the logistician will be able to confirm the shipment of the goods and organize receipt in the warehouse.

Once the collection is positioned with an estimated date, the forwarder and Logistics enter into communication. Each actor benefits from customizable vision screens with filters of your choice.

Via a manual connection or an automated flow, the forwarder will push information on the precise status of the transport. The logistician is informed in real time of compliance with the schedule. Otherwise he is able to react to his forwarder to review the distribution of batches and invoicing elements.

1. SHIPPING PROPOSALS

Using the same model, the platform will consolidate the packing lists of different suppliers and suggest to the forwarder to group shipments according to defined criteria, and with a desired shipping date.

2. THE FORWARDER SUBMITS HIS SHIPPING TO LOGISTICS

It will then give logistics visibility of shipments created with several key dates in play:

Confirmed shipment / ATD (actual time of departure) / ATA (Actual Time of Arrival) / Actual delivery date

It can also create batches within the same shipment or review the package mix by generating data from packing lists. He will also easily find the attached documentary bundle.

3. RECEIPT OF GOODS

Delivery is approaching: e-SCM will allow logistics to anticipate, through a schedule, the workload and the volume to be stored. The logistician can then have an overview of the status of each order:

ATD/ATA entered, Warehouse appointment date taken, Delivered to the warehouse, Receipt in progress

At the finest level, delivery timing can be managed using a “ warehouse calendar” in which the forwarder positions an appointment for delivery, on a date and time slot. Logistics can go so far as to assign a dock for delivery.

Finally, Receipt Monitoring allows Logistics to monitor receipts in progress or closed with stock between order and receipt. The order can remain active or be closed via a flow synchronized with the ERP.

At reception, e-SCM makes it easier to read the package labeling, standardized upstream, with all the associated data. This directly contributes to the preparation of the outgoing flow.

Thus, the TMS dimension has been strengthened to involve logistics players in collaborative work carried out via the platform. We have already set up automatic API type interfaces with several forwarders such as DHL express, Dachser, Scan Global. e-SCM thus makes it possible to impact the gains linked to the cost of transport, reception of stock, service rate, in particular with a view to subsequently optimizing its outgoing flow towards the distribution channels.